Particle getter®

Suggestions for reducing particles

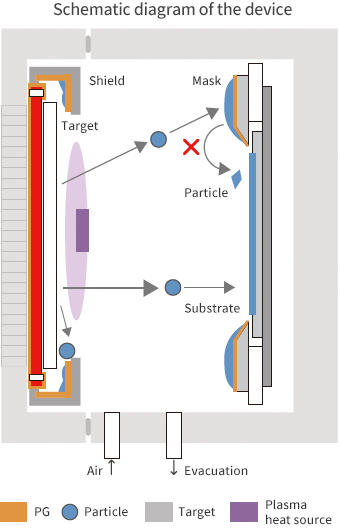

In film formation by vapor deposition and sputtering, particles adhere not only to the target but also to the mask and shield inside the device.

As the deposited film thickness increases, the risk of film peeling increases, and the peeled pieces become particles.

The PG (Particle Getter) sheet is a copper plate that has been specially processed to suppress the peeling of the film that has adhered to the inside of the equipment. Particle getter ® has a unique surface condition and excellent stress relaxation of the adhered film to suppress peeling and reduce particles.

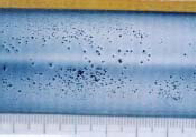

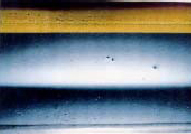

Erosion area comparison

Without PG

Without PG

After installing PG

After installing PG

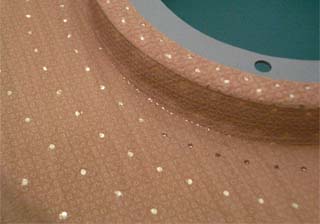

Surface comparison after film formation

Before film formation

Before film formation

After film formation

After film formation

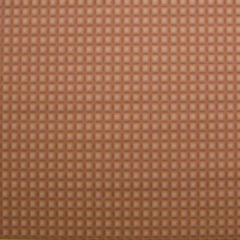

Information on PG sheet

We propose the thickness and shape of the PG sheet that is suitable for the adhesion material, equipment shape, required strength, and elongation.

70μ embossing

70μ embossing

t = 0.22mm

140μ softening embossing

140μ softening embossing

t = 0.57mm

210μ flat

210μ flat

t = 0.22mm

210μ embossing

210μ embossing

t = 0.85mm

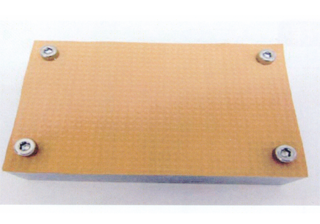

Delivery form

We can handle installation processing for parts inside the equipment (spot welding, screwing, wire fixing, bending, double-sided tape), die-cutting sheets, sheet rolls, and the required delivery form.

Processing example: Spot welding

Processing example: Spot welding

Processing example: Spot welding

Processing example: Spot welding

Processing example: Spot welding

Processing example: Spot welding

Processing example: Spot welding

Processing example: Spot welding

Processing example: screwing

Processing example: screwing

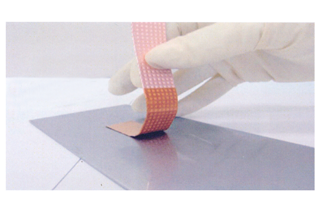

Processing example: Double-sided tape

Processing example: Double-sided tape

Sheet

Sheet

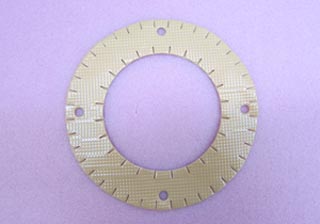

Die cutting sheet

Die cutting sheet

Contact Us

We will respond flexibly to customer's request. Please feel free to contact us.

- Contact us for products and materials

- Tel. +81-45-522-8989

Fax. +81-45-522-8993

- Other requirements(Main phone number)

- Tel. +81-45-522-8988

(Main phone number)

Main FAX number. +81-45-522-8992